As an important type of plant hormone, Jasmonin plays an important role in regulating plant growth, development and resistance responses. It also has broad application prospects. It can increase crop yields, resist pests, and can also play an important role in cosmetics and impart perfume. and the unique fragrance of skin care products.

However, the extraction of Jasmonin is indeed a difficult problem.

In traditional methods, Jasmonin mainly extracted from plants, but the plant content low and the extraction process cumbersome. The three-dimensional configuration of Jasmonin is complex, and total chemical synthesis is also difficult. The challenges faced in production limit the wide application of Jasmonin.

The development of synthetic biology has made the heterologous production of natural products possible.

On November 14, a study published in Nature Synthesis introduced a new method for the efficient, green and scalable production of jasmonic acid. This study for the first time achieved the heterologous production of the plant hormone jasmonic acid in Saccharomyces cerevisiae. Synthesized from scratch.

The successful application of this achievement not only makes the production of Jasmonin no longer limited by plant extraction and seasonal environment, but also paves the way for the large-scale application of Jasmonin in agriculture, cosmetics and other industries, and also provides opportunities for efficient and green production of Jasmonin. refer to.

This work was completed by the team of Luo Xiaozhou, a researcher at the Institute of Synthetic Biology, Shenzhen Institutes of Advanced Technology, Chinese Academy of Sciences, and Jay. D. Keasling, a professor at the University of California, Berkeley.

Building a ‘new’ microbial cell factory

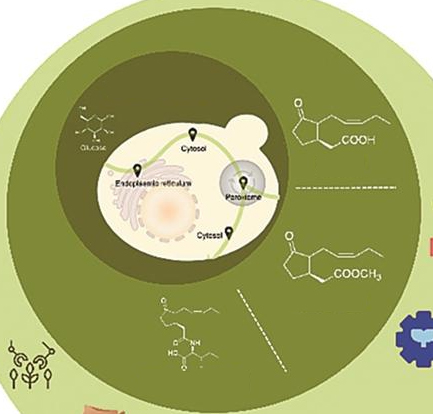

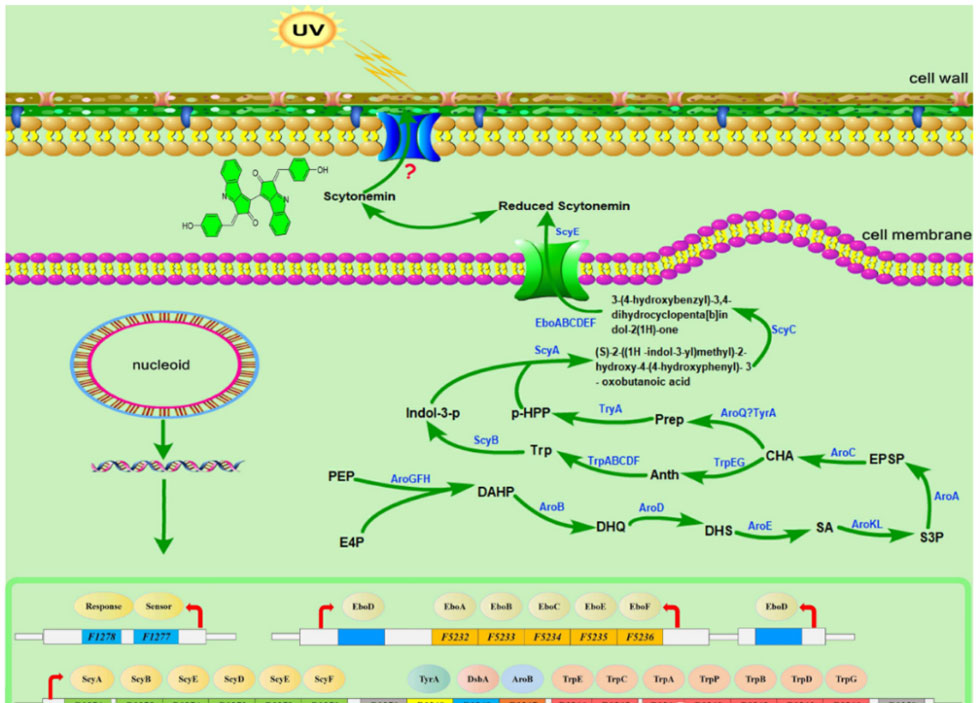

The synthesis process of Jasmonin in plants is relatively complex, with long pathways, diverse enzymatic types, and the transport of intermediate products between different organelles. The complexity of the synthesis pathway brings many challenges to the reconstruction work.

Saccharomyces cerevisiae, which is recognized as safe, contains a variety of organelles, so we prefer it as the microbial chassis for the heterologous de novo synthesis of Jasmonin.

During the experiment, the team introduced 15 exogenous genes and knocked out endogenous genes three times in Saccharomyces cerevisiae, a small microorganism with a diameter of only 8 microns, and finally achieved heterologous de novo synthesis of Jasmonin.

Through past research and experiments, it can found that finding a suitable place for the synthesis of intermediate α-LeA and OPDA in yeast the first problem to solved in pathway reconstruction. The research team spent two years synthesizing this pathway and successfully constructed a new cell factory for the green production of Jasmonin in yeast cells.

Promote green agricultural synthesis

Expected to produced on a large scale

Does establishing a Jasmonin yeast cell factory to achieve large-scale synthesis have greater advantages in yield compared to traditional plant extraction? The research team found in experiments that when jasmonic acid synthesized in the peroxisomes of yeast, the yield can reach 19 mg per liter, while the content per leaf extracted through plant extraction is only 10 to 100 nanograms.

It conceivable that the results of this research are like reprogramming the yeast factory, which can reconstructed in an environment completely different from that of plants to synthesize high value-added chemicals.

Methyl dihydroJasmonin, known as “synthetic jasmine”, one of the most commonly used additives in the fragrance industry as a derivative of Jasmonin.

“2019-2025 Global and Chinese Methyl DihydroJasmonin Market Status and Future Development Trends” points out that the global market size of methyl dihydroJasmonin will reach RMB 1.2 billion in 2025. The jasmonin market has a promising future.

Scientific breakthrough is the first step, and application of research is the key.

This work is not only a technological breakthrough, the large-scale production of jasmonic acid through synthetic biology methods also expected to become an “auxiliary equipment” for agricultural production, in the preparation of antibacterial yield-increasing compositions, preparation of pest pesticides, and preparation of fruit and vegetable colorants, etc. The agricultural sector has unlimited potential.

The technology offers a more efficient, economical and environmentally friendly approach compared to current chemical synthesis or extraction processes.

The research team is already exploring ways to expand production, aiming to give this “green” technology more industrial viability.

Lorem Ipsum is simply dummy text of the printing and typesetting industry.