Acetoin is an organic compound that is mainly used as a flavor, in the preparation of cream, dairy, yogurt and strawberries, and in organic synthesis.

It is widely used in many fields such as food, pharmaceutical and cosmetics.

Acetoin is mainly synthesized chemically in industry, but this method relies on non-renewable fossil raw materials, and the free radical substitution reaction in the production process can cause damage to the environment.

Therefore, scientists have turned their attention to microbial fermentation methods, among which Bacillus subtilis is regarded as an ideal microorganism for producing acetoin because of its high safety, wide range of substrate utilization and strong gene editing operation.

However, the production of acetoin by Bacillus subtilis often faced with the problems of low production efficiency, long fermentation cycle and high cost.

Recently, A study led by Professor Zhang Xian’s team at Jiangnan University entitled “Efficient Acetoin Production in Bacillus subtilis by MultivariateModular Metabolic Engineering” The study of “Spatiotemporal Modulation” has successfully overcome these problems.

Researchers have successfully utilized Bacillus subtilis to efficiently convert glucose into ethoin through strategies such as multivariate modular metabolic engineering and spatiotemporal regulation.

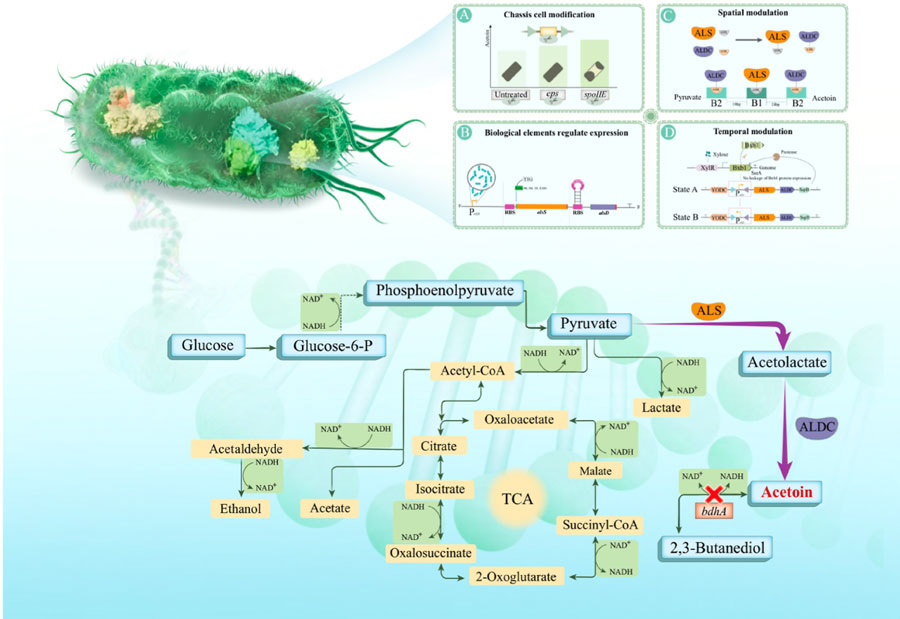

The researchers selected wild-type Bacillus subtilis JNA 3-10 as the base strain. Through gene editing technology, the researchers cloned some key genes in Bacillus subtilis, such as alsS, alsD and yodC;

Zinc finger protein coding sequence, binding base sequence, serine integrase Bxb1 logic gate sequence synthesized.

By using fusion PCR technology, different gene fragments cleverly connected, fusion protein genes constructed and inserted into specific plasmids, and initial strain BM obtained, initially achieving the conversion of glucose into acetoin.

Subsequently, the researchers adopted various strategies to transform and upgrade the strain.

Deletion of non-essential functional genes to redistribute carbon flux

The researchers found that if some of the non-essential genes in Bacillus subtilis deleted, the consumption of energy and substances by non-essential metabolic activities, such as eps gene clusters and spoIIE genes, could reduced.

The eps gene encodes extracellular polysaccharides, which together with proteins and nucleic acids form the biofilm of Bacillus subtilis.

Under the conditions of adequate nutrition and suitable environment for the fermentation of acetoin, deletion of eps gene clusters does not cause additional burden on cell physiology, but can save energy for cell growth and product synthesis.

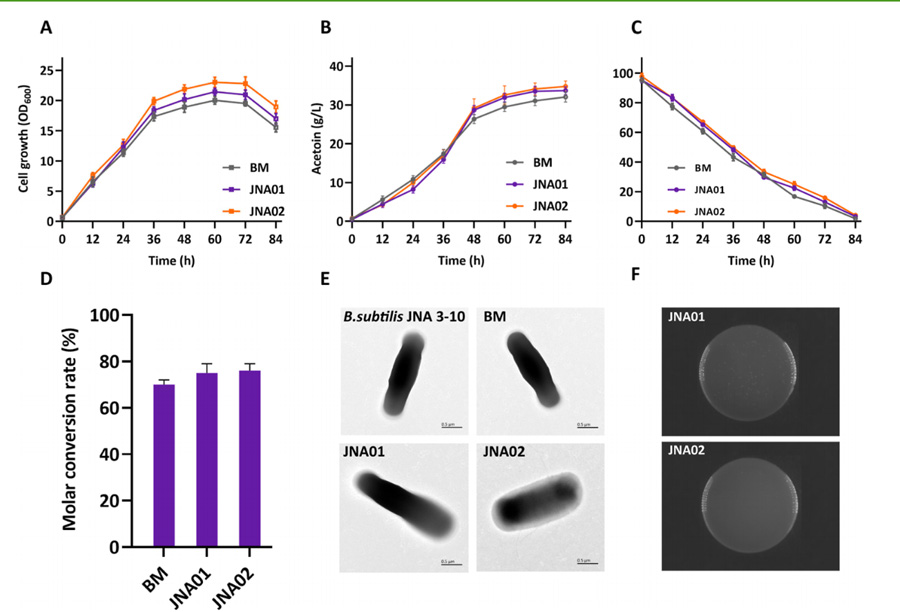

The results showed that the maximum biomass of recombinant strain JNA01 deleted eps gene cluster increased significantly.

Compared to the original strain BM, OD₆₀₀ maintained at about 21 at stable stage.

When JNA01 consumes the same amount of substrate, the production of acetoin is higher.

JNA02 obtained after spoIIE, another gene of JNA01 knocked out.

Although the strain could not form a complete oval spore after knockout, its OD₆₀₀ maximum value and ethanoin production were 23.0 and 34.8 g/L, respectively.

Compared with the original strain BM and the recombinant strain JNA01, the molar conversion rate of acetoin in JNA02 increased by 6%.

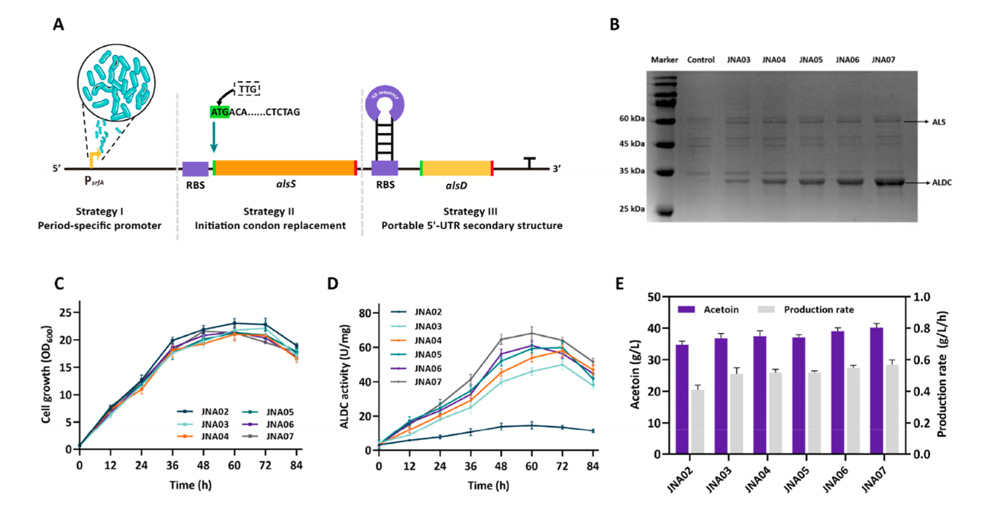

Promote the expression of core enzymes ALS and ALDC

Two enzymes, ALS and ALDC, play key roles in acetoin synthesis.

The researchers utilized the cycle-specific promoter PsrfA and optimized the initiation codon and introduced the 5 ‘-UTR sequence to regulate the expression of both enzymes.

After optimization, the enzyme activity of ALS increased by 1.4 times, and the enzyme activity of ALDC was up to 68.2 U/mg, which was 5.09 times.

The maximum titer of etoin of recombinant strain JNA07 reached 40.2 g/L, which 1.2 times that of the previous strain, the production rate 1.4 times, and the efficiency upgraded again.

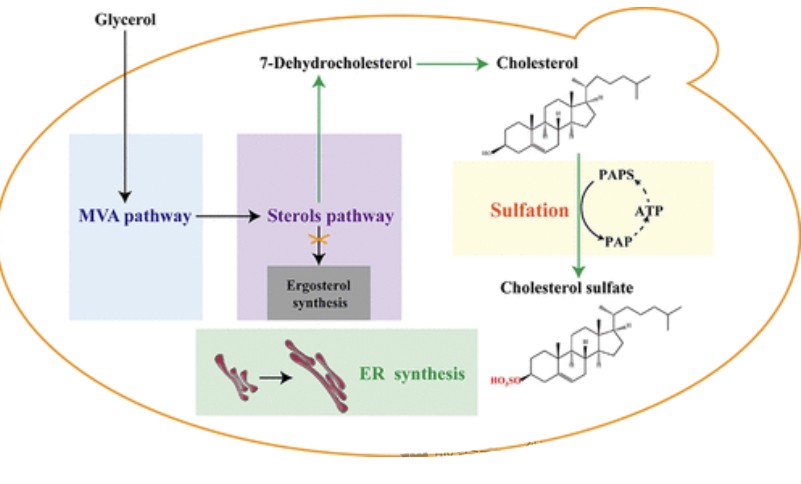

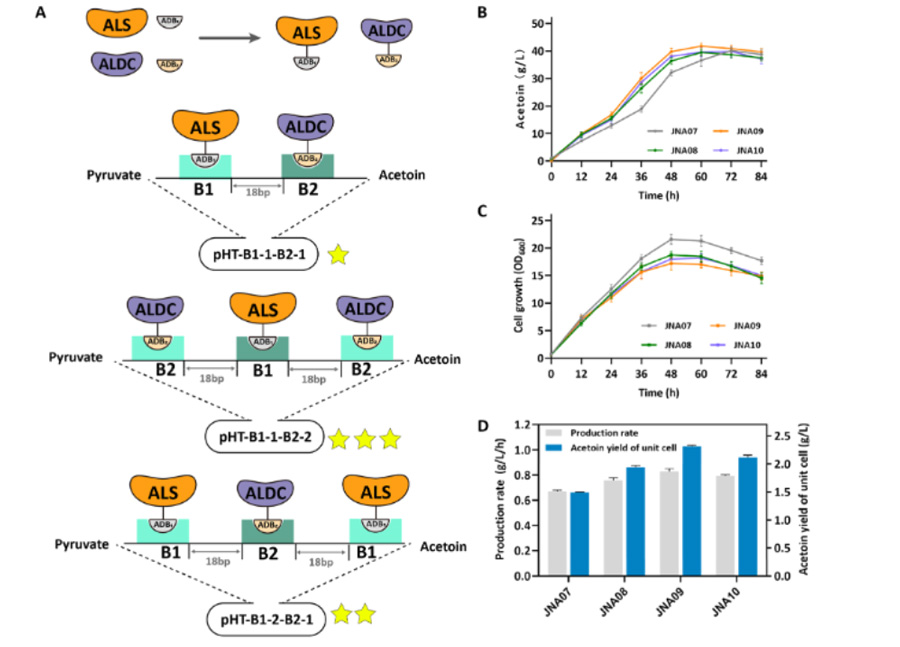

efficiency of acetoin synthesis was improved by using DNA scaffold

In the experimental procedure, when Bacillus subtilis catalyzes the conversion of pyruvate to acetoin, the intermediate α-acetyllactic acid is unstable and will spontaneously decarboxylate to form diacetyl under aerobic conditions.

Therefore, the rapid and efficient catalytic conversion of alpha-acetolactic acid to acetoin is essential for acetoin production.

In biological cytoplasm, when DNA scaffolds containing corresponding zinc finger binding sites are present in cells, DNA scaffolds will bind specifically to modified fusion proteins.

The researchers used plasmids as stable and configurable DNA scaffolds that balance and regulate the anchoring ratios of different proteins.

Colocalization and proximal alignment of ALS and ALDC by stents with different ratios of ALS and ALDC binding sequences (1:1, 1:2, and 2:1) showed that this strategy significantly improved ethanoin productivity and varied with scaffold structure ratio.

At 36 h fermentation, the acetoin yield of recombinant strains JNA08, JNA09 and JNA10 was 1.40, 1.59 and 1.51 times that of recombinant strains JNA07, respectively.

Logic gate circuits regulate metabolic pathway cofactor levels and enhance energy supply

Intracellular levels of NAD + and NADH during fermentation greatly influence ethoin synthesis.

The scientists used the serine integrase Bxb1 to construct a logical gate circuit to induce NADH oxidase expression at 48 h of fermentation.

The results showed a marked increase in the level of intracellular NAD plus in the recombinant strain JNA11N, as well as an increase in the rate of ethoin production and glucose consumption.

The maximum titer of etoin in JNA11N 44.3 g/L, and the NADH-dependent by-products significantly reduced, but the titer of acetic acid increased.

The researchers speculate that this phenomenon is mainly because the DNA scaffold structure prevents the enzyme in the acetoin synthesis pathway from spreading in the cell, shorting the reaction distance in the cell, further protecting the unstable intermediates, preventing competition between different pathways for the substrate, and ultimately promoting the orderly progress of the enzyme reaction.

After the metabolic engineering of Bacillus subtilis by deleting non-essential genes, optimizing the expression of key enzymes, using DNA scaffolds and logic gates, the production efficiency of acetoin significantly improved.

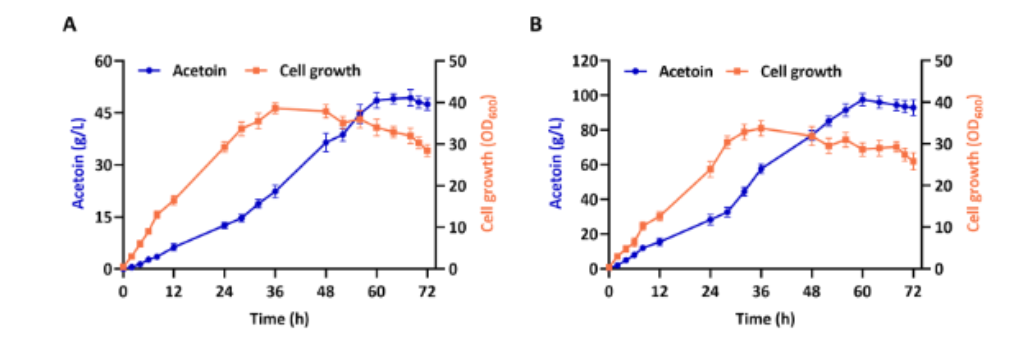

The recombinant strain JNA11N and the initial strain BM were fed in a 5 L bioreactor, and JNA11N showed strong production capacity.

The most efficient price of ethoin reached 97.5 g/L, and the production rate 1.81 g/L/h, which 1.97 times and 2.24 times of BM (original strain), and the accumulation of by-products such as 2, 3-butanediol significantly reduced.

This means that the team has successfully provided a new way to efficiently produce acetoin using Bacillus subtilis.

Reference: 1. https://pubs.acs.org/doi/10.1021/acssuschemeng.4c06511?articleRef=test (