Astaxanthin is a kind of carotenoid with strong antioxidant ability, which has been widely used in health care, medicine, cosmetics, food additives and aquaculture.

With the increasing demand for natural products, the microbial production of astaxanthin has become a new hotspot.

Recently, Professor Wenming Zhang and Professor Feng Xin of Nanjing University of Technology published a paper titled “Microbial astaxanthin synthesis by Komagataella” in the Journal of Agricultural and Food Chemistry phaffii through the metabolic and fermentation engineering “research paper, doctoral student Jingnan Wang is the first author of the paper.

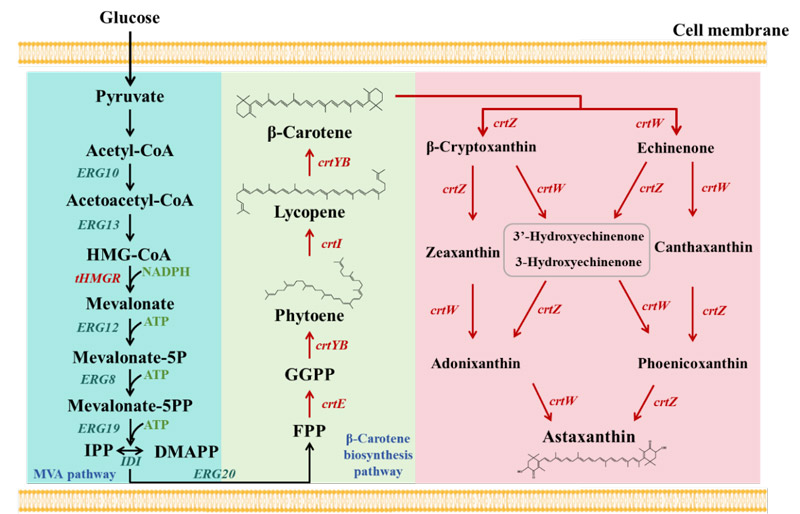

In this study, the heterosynthesis of L-astaxanthin was successfully achieved by metabolic engineering of Pichia Pasteuris.

The research team first investigated the enzymatic properties of β-carotene ketoolase and β-carotene hydroxylase, the key enzymes of astaxanthin synthesis, and improved the activity of the key enzymes through self-assembly and enzyme fusion to enhance the conversion efficiency of β-carotene.

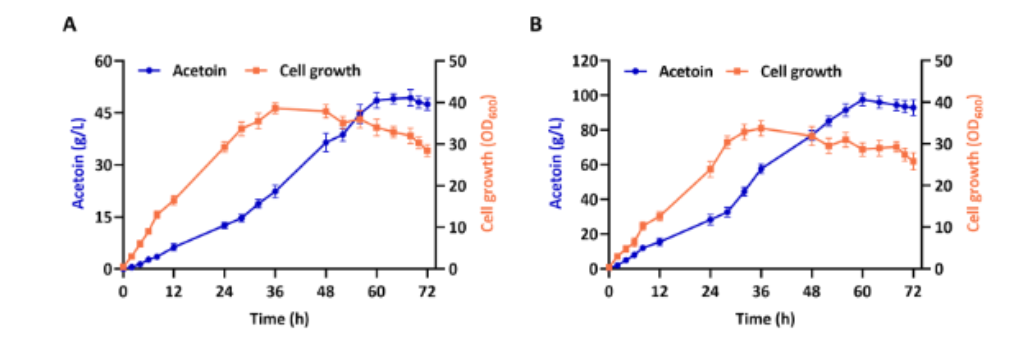

Subsequently, through the optimization of cofactor engineering and fermentation engineering, the astaxanthin yield reached 178.99 mg/L in shaker fermentation and 716.13 mg/L in 5 L bioreactor, which provided the highest yield for astaxanthin synthesis by Pichia Pasteuris and provided technical support for the production of novel antioxidant feeding protein.

The full name of astaxanthin is 3,3 ‘-dihydroxy-beta-carotene-4, 4’ -one, which has stronger antioxidant activity than vitamin E (more than 500 times), can effectively inhibit oxidative damage and cancer of cells, and also has many effects such as anti-hypertension, prevention of cardiovascular diseases, and enhancement of immunity.

It has been widely used in animal feed, health food, cosmetics and medical preparations.

The European Union has approved astaxanthin for use as a dietary supplement, the U.S. Food and Drug Administration (FDA) has also approved astaxanthin for use as a food colorant in animal and fish feeds, and China also allows the use of astaxanthin in food and feed additives.

With the increasing demand for natural products, the market size of astaxanthin expected to reach $3.4 billion by 2027.

At present, astaxanthin production methods include natural extraction, chemical synthesis and microbial fermentation.

The natural extraction has low yield and high cost, and the chemical synthesis process is complex and high cost and will produce toxic by-products.

Microbial fermentation has attracted more and more attention because of its environmental protection and high efficiency.

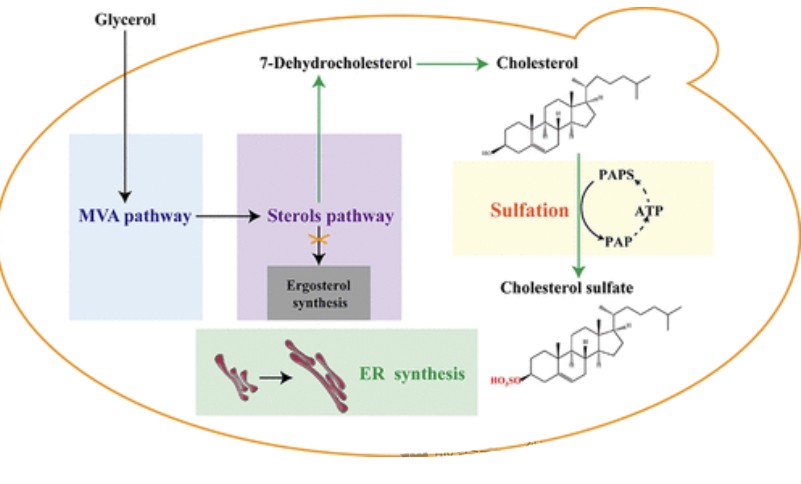

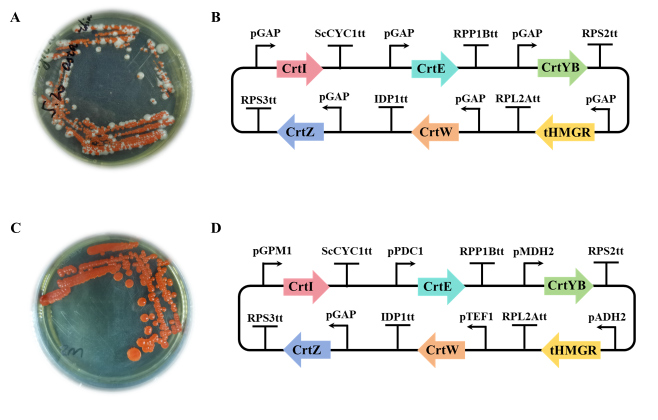

In the future, the researchers integrated the astaxanthin synthesis pathway derived from Rhodococcus pluvium into the genome of Pichia Pasteuris and were able to synthesize L-astaxanthin de novo using glucose.

In order to solve the problem of strain degradation in astaxanthin synthetic strains, the researchers replaced different promoters for each gene of the synthetic pathway and obtained an engineered strain that could produce astaxanthin stably.

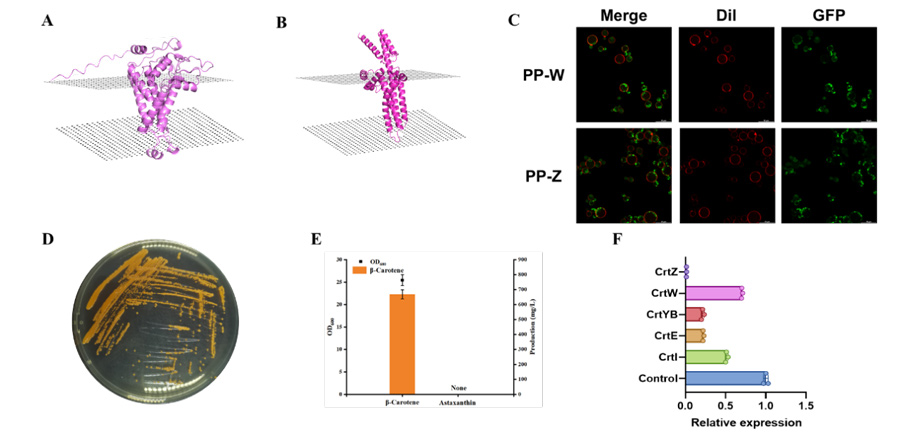

The enzymatic properties of β-carotene ketoolase (CrtW) and β-carotene hydroxylase (CrtZ), the key enzymes in astaxanthin synthesis pathway, investigated.

The two proteins verified as membrane proteins by laser scanning confocal microscopy (CLSM), and their effects on other enzymes in astaxanthin synthesis pathway investigated by qRT-PCR.

Based on this, self-assembly and enzyme fusion of CrtW and CrtZ performed to reduce the transport distance of intermediate metabolites and increase enzyme activity.

The synthesis process of astaxanthin requires the participation of NADPH, and the researchers will introduce the NADPH regeneration pathway from saccharomyces cerevisiae into Pichia Pasteuris to construct the cofactor project.

Studies have shown that with the cofactor strategy, the intracellular NADPH content increased by two times, and the transcription level of key genes in astaxanthin synthesis pathway significantly improved.

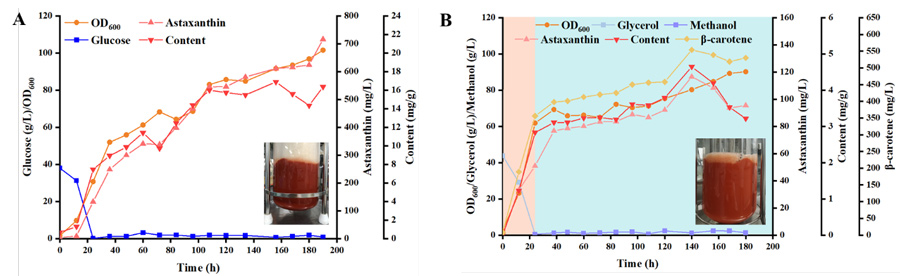

By optimizing culture conditions, including temperature, carbon source type, carbon source concentration and nitrogen source type, astaxanthin production further improved.

The production of astaxanthin increased to 178.99 mg/L by adding metal ions, BHT and Tween-80.

In continuous feed fermentation in a 5 L bioreactor, the engineered bacteria could produce 716.13 mg/L astaxanthin using glucose as the only carbon source, which was the highest level of astaxanthin production in Pichia Pasteuris.

Astaxanthin synthesized from methanol as the only carbon source for the first time.

Reference links: 1. https://pubs.acs.org/doi/full/10.1021/acs.jafc.4c10113